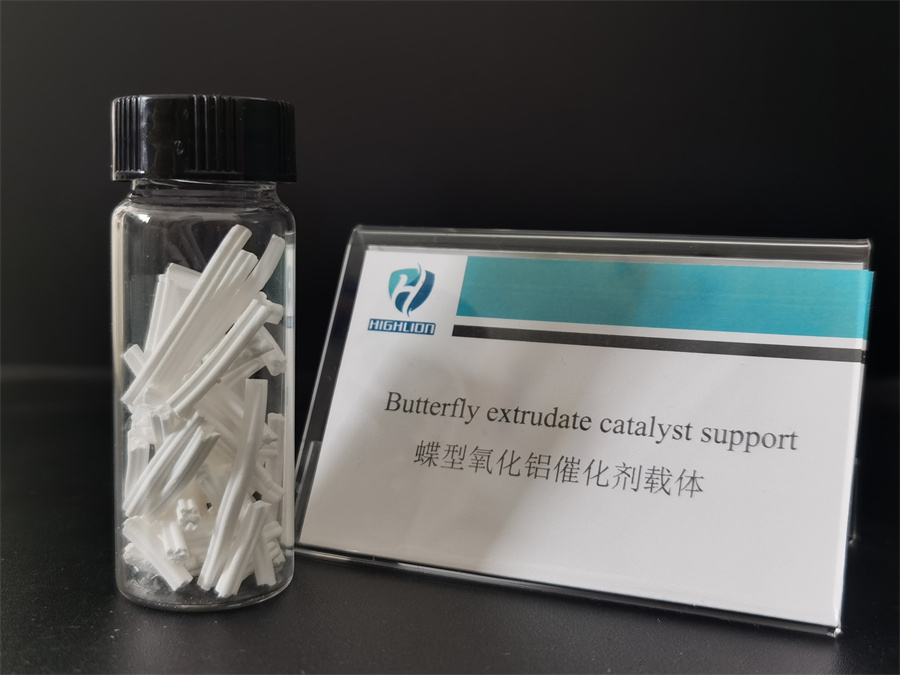

Four-leaf clover alumina catalyst carrier

Four-leaf clover alumina catalyst carrier

-. Shape: Four-leaf clover shape

-. Size: Diameter = 1.2~6.0 mm

-. Length: = 3.0~15.0 mm

-. Specific surface area: 200-400m2/g

-. Bulk density: 0.4-0.9g/ml

-. Radial strength: ≥100N/cm

Four-leaf clover alumina catalyst carrier compared to Other Shapes(such as spherical, cylindrical, trilobe etc),have following advantages:

2. Optimized Hydrodynamic Performance

– The Four-leaf clover ensures more uniform fluid distribution in fixed-bed reactors, minimizing channeling and improving reaction homogeneity.

– Compared to trilobe supports, the Four-leaf clover shape maintains high mechanical strength while further reducing pressure drop, making it suitable for high-flow reactions (e.g., hydroprocessing, reforming).

3. Superior Mechanical Strength

– The symmetrical design of Four-leaf clover supports provides higher crush strength than trilobe or some honeycomb structures, reducing breakage risks during loading or operation.

4. Enhanced Active Metal Loading Capacity

– The grooves and porous structure facilitate highly dispersed deposition of active metals (e.g., Ni, Mo, Co), improving catalytic activity and stability.

– Compared to spherical supports, Four-leaf clover carriers allow higher metal loading while minimizing sintering risks.

5. Broad Applicability in Catalytic Reactions

Four-leaf clover alumina catalyst carrier are widely used in:

– Petroleum refining (hydrotreating, hydrocracking, reforming)

– Chemical catalysis (Fischer-Tropsch synthesis, selective hydrogenation)

– Environmental catalysis (SCR denitrification, VOC abatement)